‘Drive it hard, drive it fast, break it..’

REGARDLESS of any misgivings you may have about the success of failure of Supercars Generation 3 rollout, there’s no doubt that it’s making for fascinating stories as the sport seeks to develop essentially a whole new platform for the future. Supercars legend Craig Lowndes has been leading the development charge on the GM side of the equation, and tells TRT that they have been given free reign to, quite literally, drive it until it breaks.

WHEN IT comes to knowing a thing or two about Touring Car Racing, Craig Lowndes is probably a decent enough go-to guy.

After all, he made his debut in what was then the Group A Touring Cars in 1994 when the cars were not overtly far removed from their road going brethren.

From his full-time debut in 1996 through to his current stint as a co-driver at Triple Eight Racing he’s driven everything from Group A to Project Blueprint, Car of the Future and now, Generation 3.

Well, at least the engine package currently being developed for the next chapter in Supercars’ history.

The seven-time Bathurst champion has been one of the drivers behind the early development of the Chevrolet-based powerplant that will power the Gen 3 Camaros when they make their debut mid-way through the season next year.

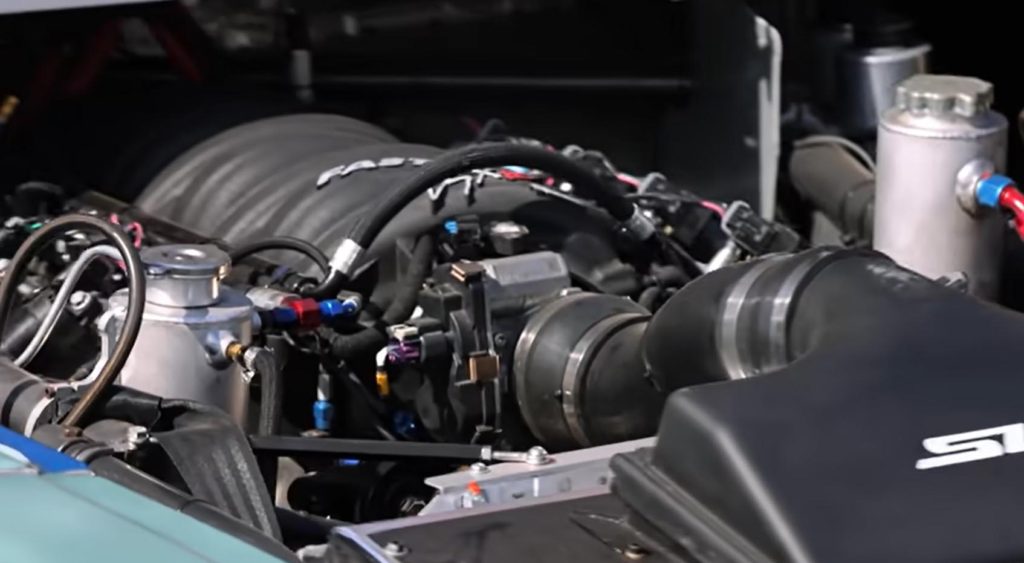

With the 5.7-litre ‘crate’ chevy engine bolted into a TA2 car sourced from Asia, the first engine made its social media debut a few weeks back and is the first major step in sorting out the technical make-up of what is the biggest overhaul of Supercar specs since Car of the Future became a thing in 2013.

“It’s a good test mule,” Lowndes said of the car on a recent edition of the On the Grid Podcast.

That car in question is a Mercedes-Benz bodied TA2 (Trans Am to you and I) car sourced from Malaysia and the connections of fellow Triple Eight driver, Prince Jefri Ibrahim, who races in the team’s GT program.

Running a five-speed paddle shift gearbox, in another potential nod to the categories future, the TA2 platform is the perfect test mule for the Chevrolet-based Supercars engine, given it shares close DNA with the spec powerplant used in the series both here and in Asia.

“We’ve done three days in the vehicle. The first day Shane, Jamie and Broc Feeney did a lot of the installation side of it. I’ve done days two and day three, and also on Day 3 Shane (van Gisbergen) came out to be part of it to get more of a perspective on the current Supercar and what he wants from it in a sense.”

Gen 3 will introduce a raft of different systems to the world of Supercar racing that will fundamentally change the technical make-up of the engine and driveline package.

Chief among which is an all-electronic fly-by-wire throttle, which removes the mechanical link between right foot and throttle body and replaces it with a computer-controlled solenoid.

Current Supercars engines use a series of eight carbon fibre inlet trumpets to suck air into the engine. The IP around the inlet systems on the various Ford and GM-based engines is all closely guarded among teams and engine builders, which is why it is rare you’ll ever see under the bonnet of a Supercar without the massive Carbon Fibre airbox shrouding all the interesting bits.

While the current system provides razor-sharp throttle response and allows the engine to breathe superbly, the rate of development for increasingly small gains means it’s an expense the sport just doesn’t need.

The new engine rules will mandate a single throttle body at the entrance to the engine inlet, almost identical to what you will see if you lift the bonnet and remove the plastic covers on a current Ford Mustang or V8-powered Commodore.

Lowndes says it’s taken some time to tune both the car and the driver to work as desired, but it’s not without its advantages.

“It is different. It’s a fly by wire system, so getting the throttle pedal to talk to the butterfly. It’s a crate engine which has a single butterfly (on the throttle body) rather than the eight trumpets.

“The first mission was to get the throttle pedal to talk to the butterfly in the way that it works.

“The beauty about the fly by wire is you can program it. You can be aggressive, you can be linear, you can program it to suit whatever the driver wants.

“That element going forward will be really good, especially for a wet weather, you’ll be able to program it to dull it down so it’s not as peaky. That aid will be a real benefit in the Gen 3 program.

“Once we’ve got that setup, it’s the butterfly and the engine in sense of the mapping,” he added.

As ever, the drivability of the engine – the way it behaves – is more important to get right than merely winning the horsepower race.

After all, Lowndes noted, there’s not much point having all the grunt in the world if you can’t use it.

“Down low, up high, mid-range – Getting that sorted was really important. I think we got a handle on that side of it pretty well now. There’s more tuning to be done.

“At the moment the engine starts, it runs, it drives. Some of the complexities in the early stages was driving it out of pit lane on the limiter, getting that drivability – It’s not all about horsepower, it’s drivability.

“At the beginning we couldn’t get out of pit lane on the limiter, to give it a rev to drive it off. We’ve cleaned all that up, now we can drive in and out of the pit bay on the limiter.

“There’s a whole lot of facets of just getting it right, not just outright speed or horsepower.”

Lowndes confirmed that the team has been given carte blanche to drive the engine to destruction in a bid to prove it’s durability – one of the key elements of the entire Gen 3 engine program is dramatically reducing engine costs by dramatically increasing their lifespan between costly rebuilds.

For drivers used to being in the business of exercising ‘mechanical sympathy’, naturally this hasn’t proved to be an overly onerous task for the driving squad.

“At the moment we’ve done close to 1500km on the engine and, touch wood, it hasn’t had a problem,” Lowndes said.

“The category wants to keep going until we find the first problem.. it’s very rare you get a chance to drive something and you’re told ‘drive it hard, drive it fast, break it..’ I was like: ‘YES!’.

“At the moment we haven’t broken it, but In saying that, we’ve found some little things that have gone wrong – at one point, we had a spark plug lead come off the ignition module on the rocket cover. Shane came back and said it had dropped a cylinder and we thought, ‘here we go, this is the first sign’, but it turned out to be a spark plug lead.

“We plugged it back on and away we went again!”

The process continues apace, with the development of Supercars’ new technical future now beginning to accelerate after COVID-19 related delays pushed back the planned introduction of the often controversial program.

Lowndes says the end goal is to deliver a product that can be, for all intents and purposes, a ‘turn key’ product for GM-based teams when the time comes.

“All those things we just need to find out so that when the engine is delivered to the teams, we’ve got rid a lot of 99% of the bugs.”